These are all of Ricky’s actual notes on our meadery operation and the mead we make. There might be profanity, usually of the late 19th Century variety. The only redactions are to remove the names of people and businesses when deemed appropriate. Footnotes provided by Jess and Kelly.

7/11

Microscopic corrosion on the fill sensor is behind the weird overfill issues. It was also the reason we were seeing slower fill speeds on that head since it was dawdling at the end.

7/12

New canning checklist is getting its third set of eyeballs. [Converted the link to a document at the end of this for folks following along at home.]

Cleaning sensor hasn’t solved the problem. Near side 2 is totally overfilling. Making adjustments worked for a while, but now it’s time for a call to Alpha!

Jake swapped wires and we’ve shown that it’s something in the sensor itself. New one should be here next week.

7/13

Bragi has started refermenting! Luckily there’s practically no sugar left, but I let it rest for months! Still tastes amazing. Hopefully it’s all done by next week.

7/14

We ran out of SaniClean, so I decided to run our CIP with StarSan… the results were… beautiful, in their own way.

Even the video barely does it justice:

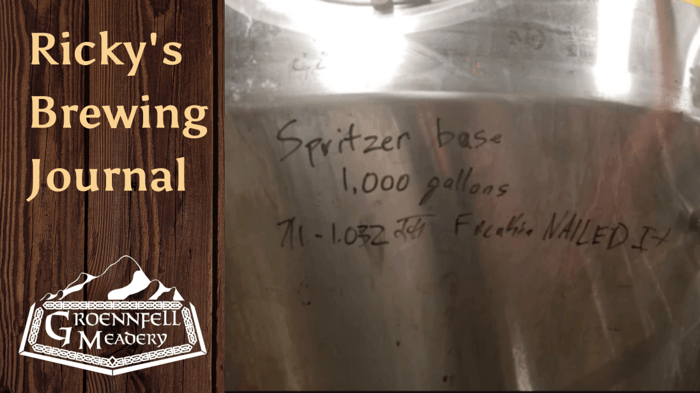

Got both spritzers into their final tanks!

7/15

Spritzers taste fantastic! Hope they’ll be done final fermentation by Monday.

Canning Startup Checklist

- Confirm Tank Temp and Check Chiller

- Connect and Turn on Head Pressure to Tank

- Turn on Printer

- Start Jet

- Turn on Water to Canning Line

- Turn on Air to Depal and Canning Line

- Turn on Air to PakTech

- Plug in PakTech

- Turn on Labeler

- Turn on CO2 to Machine

- Enter Date Code and Start Printer

- Connect Main Line

- Get Additional Lids and PakTechs

- Get case trays

- Get Pallets

- Clear Slip Sheets

- Clear Area

- Fill Lids

- Install Labels

- Bucket with Pump Under the Rinse

- Can bucket

- Change Speed on Herbert (admin admin)

- Clear Counts

- Start Canning Line

- Start Depal

- Last Potty Break

- Start Labeller

- Start PackTech